Dear steemains!!

Today i'm going to share the full process of making a Basic T-Shirt in Garments industries and dedicated this post for those people who are working hard to make a beautiful T-Shirt for us.

image src Basic T-Shirt is most popular fashion item in whole world, because of it's variation style, and it's so comfortable to wear, it also popular for it's law rate comparing with other fashion wear.

How many people in the world know about the process of making a basic T-Shirt, how many labor work to make a T-Shirt for us. It's a very long process, i'm going to describe about all process of making a basic T-Shirt.

Bangladesh is very popular for manufacturing cloths and for it's quality. Foreign buyer give order directly or via buying house in Bangladesh. After getting a order, Concern Garments industries merchandising Marketing team, analyze the total process of following order. And selected merchandiser started to follow the total process of manufacturing.

1. Calculating Fabrics consumption:

After getting order tag file, concern merchandiser deeply study that, then he calculate how many fabrics will need to make total quantity of following order that provided by buyer, depending on the quantity. Basic T-shirt specially made on knitted fabrics, fabrics quality is mentioned in order sheet, it's depend on buyer requirement, Fabrics construction and composition depend on buyer requirement, after calculating the consumption merchandiser, calculate how many yarn will need to those garments. Yarn depends on buyer requirements. Here i'm going to mention some mostly uses yarn,

- 100% Cotton Karded.

- 90% Cotton 10% Viscose, CVC

- 95% Cotton 5% Polyester. CVC

- 60% Cotton 40% Polyester, CVC.

- 50% Cotton 50% Polyester, PC.

According to order style yarn merchandiser buy yarn form spinning mills.

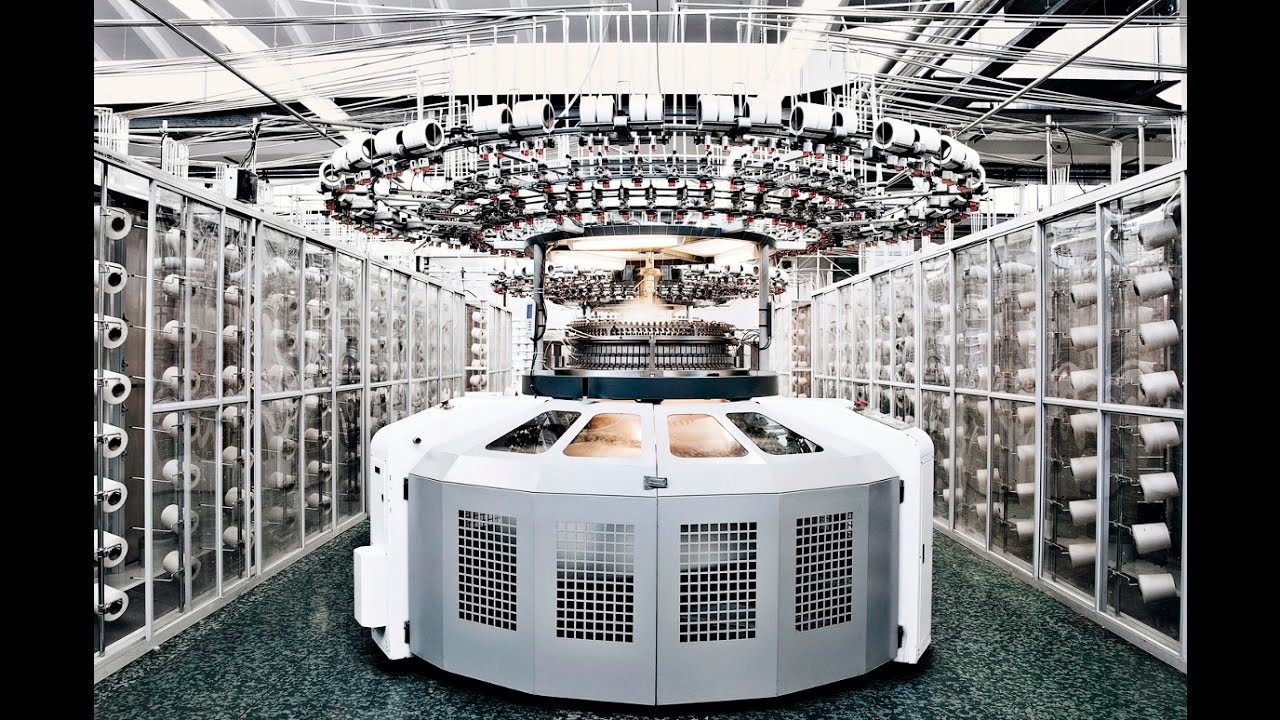

2. Knitting Process:

After receiving yarn from spinning mills, concern merchandiser send it for knitting, Based on construction of fabrics, There have lot of variety of fabrics construction,

Single Jersey. Pique, Fleece, Lycra Single Jersey, Rib 1x1, Rib 2x2, French Terry. Interlock e.t.c. After knitting process fabrics are made. It's call grey fabrics.

image src

Fabrics Dyeing:

After knitting, based on T-Shirt Color have to dyeing the fabrics, there have lot of process of dyeing. It's depends on buyer requirement.

- Color dyeing.

- Enzyme.

- Stenter

- Squeding.

- Compacting.

After dyeing process the fabrics comes for finishing process. In finishing section Quality controller check out the fabrics GSM and find out the fault of fabrics.

Img src

All over Print:

There have a two kind of printing, firstly All over print, Second Screen print. If buyer asked for AOP, after finishing fabrics have to do this process depending on t-shirt printing design. Some popular type of AOP, Discharge print, Pigment print, Rubber print, Flo recent E.t.c

Cutting process:

If Aop is available on Style after AOP fabrics are send for cutting based on Sizes, a basic T-shirt have following parts, front part of body, back part of body, collar, piping, sleeves. All part are have to cut separately with held of CAD pattern.

Screen print:

If Screen print is available on style, after cutting, cutting part's are send for screen print. print is depend on printing design provided by buyer. Some popular screen print, HD print, puff printing, Rubber print, water print, Glitter print e.t.c

Sewing:

After printing all cutting parts a send to sewing division to sewing the product, garments sewing operator joint all parts of garments by sewing.

img src

Finishing:

After sewing cutting parts turn into ready made garments, and it's send to finishing section for iron it. After iron the garments. it's send to Packaging section.

This way a ready made are made, many process have to do for completing a Basic T-Shirt, then it's make ready for use.

We have to show respect those people who are involve to make a ready made Garments for us.